By Nazakat Ali – Watt Vission

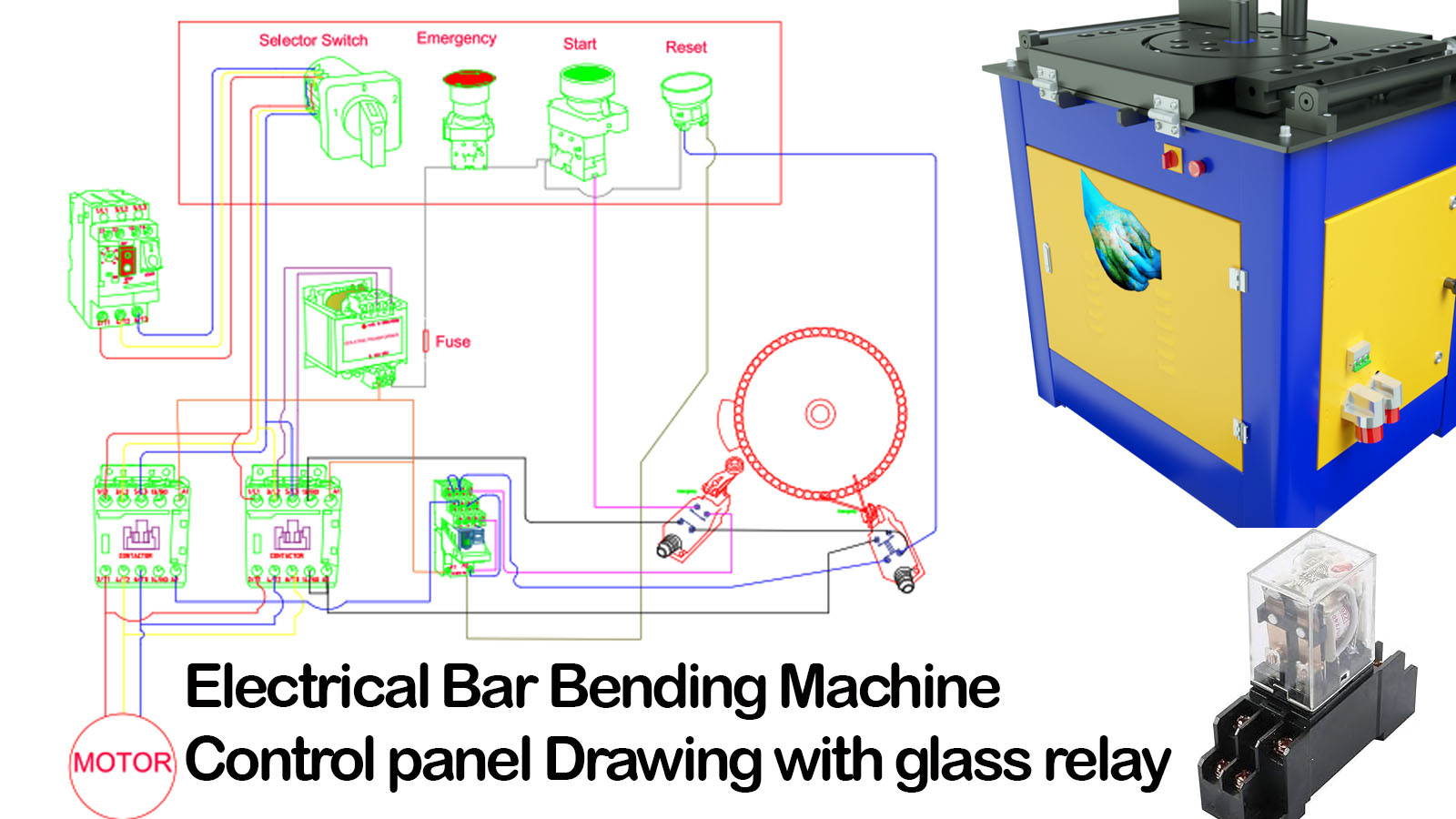

The control panel for a bar bending machine is designed to efficiently control the motor and ensure safe operation during the bending process. Below is a detailed explanation of the wiring setup, based on the provided diagram.

Key Components:

- Selector Switch: Used to control the machine’s operational modes (on/off).

- Emergency Stop: Instantly cuts power to the machine in case of an emergency.

- Start and Reset Buttons: The start button powers up the machine, while the reset button resets the system after a fault.

- Fuse: Protects the circuit by breaking the connection in case of overcurrent.

- Contactors: Control the motor’s operation by switching power on or off.

- Glass Relay: Controls current flow and acts as a safeguard.

- Motor: Drives the bending mechanism.

- Limit Switches: Automatically stop the motor once the bending limit is reached to prevent overbending.

Wiring Breakdown:

- Main Power Supply:

- The main power supply is connected to the selector switch, which allows the operator to turn the machine on or off.

- Emergency Stop:

- The emergency stop button is wired in series with the power supply. Pressing it instantly cuts off the current, stopping the machine in emergencies.

- Start and Reset Buttons:

- The start button is wired to activate the motor through the relay and contactors. The reset button clears any faults and resumes normal operation after an interruption.

- Fuse:

- The fuse is placed before the contactor to protect the system. If too much current flows, the fuse disconnects the circuit, preventing damage to the motor or other parts.

- Contactors:

- The contactors are wired to the motor and control its power. When the contactor is engaged, it passes high-power current to the motor, enabling the bending process.

- Motor Wiring:

- The motor is connected to the output side of the contactor. When the contactor is energized, it powers the motor for the bending operation.

- Limit Switches:

- Limit switches are connected in series with the motor. They stop the motor automatically when the bar reaches the required bend angle, ensuring that the material is not over-bent or damaged.

- Glass Relay:

- The glass relay manages the motor’s on/off function by controlling the contactors. When the start button is pressed, the relay engages the contactors, and the motor begins running. If the stop button or limit switch is triggered, the relay deactivates the contactors, halting the motor.

Conclusion

This wiring setup is essential for the smooth and safe operation of a bar bending machine. Each component ensures manual control as well as automatic safety features to protect the system and the operator. By following this wiring diagram, you can guarantee a reliable, efficient setup for your bar bending machine.

This guide is brought to you by Nazakat Ali in collaboration with Watt Vission, where we provide valuable insights on electrical systems and machinery for professionals and enthusiasts alike.